WEAFs Operations Director, Belinda Austin, attended a meeting at Bridgwater College yesterday evening (29th April 24), to keep abreast of how plans for the new Agratas Giga factory are progressing. The factory is set to be constructed at the Gravity Smart Campus site in Puriton, Bridgwater.

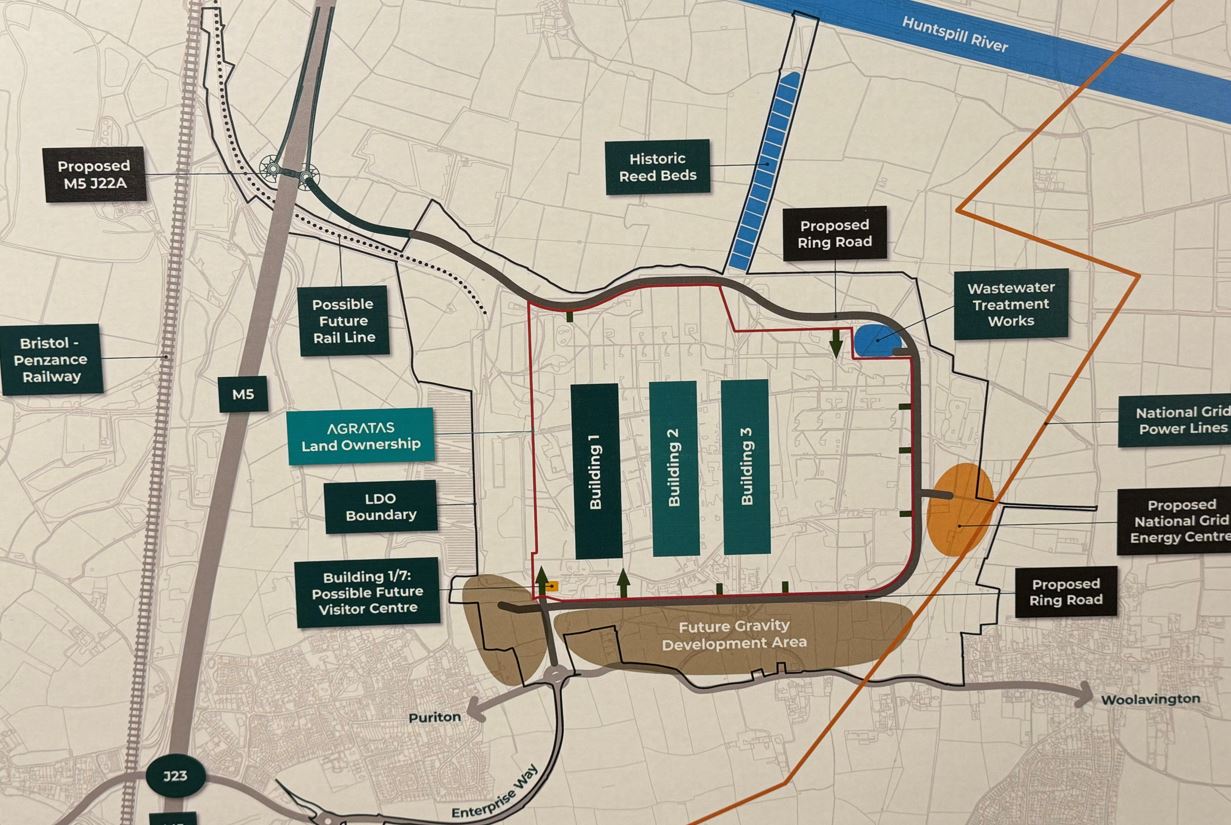

Gravity Ltd acquired the former Royal Ordnance Factory Bridgwater site in 2017, and it has since been designated an Enterprise Zone to encourage business investment. In 2024, Agratas, Tata Group’s new global battery business, purchased the 308-acre Gravity site to construct a Giga factory which aims to significantly impact Somerset’s economy and the UK’s green energy transition.

Agratas is focused on designing, developing, and manufacturing high-quality, high-performance sustainable batteries. The company’s R&D Innovation Hubs in India and the UK are collaborating with leading universities and research institutions to drive technological breakthroughs in battery technology. The Giga factory in Bridgwater is expected to be a key component in the UK’s transition to a green economy, with a focus on sustainability and clean energy.

The facilities are designed to be powered by clean sources of electricity, including purpose-built renewable energy plants, to support the goal of 100% clean power across all of operations.

The construction of the factory will proceed in phases, with Building One set for test piling in spring 2024, piling in early summer 2024, and full construction commencing in autumn 2024. Production is scheduled to start in 2026, with the facility becoming fully operational by early 2027. By 2030, the site is expected to operate at full capacity.

Agratas recruitment plan aims to create 1,400 jobs when Building One becomes fully operational between 2025 and 2026, with demand-led scale-up by 2027-2028. The company’s goal is to reach 4,000 jobs by 2029-2030. Agratas is working closely with Bridgwater & Taunton College and other local and regional partners, including Somerset Council, to design bespoke education and training programmes, ensuring local jobs for local people.

The new Giga factory will support the UK’s electric vehicle and energy storage sectors, helping to create a sophisticated circular economy ecosystem. The facility’s design will prioritise sustainability, with plans to use clean sources of electricity and adopt a resource-efficient approach that emphasises reuse, recycling, and recovery of materials.

Belinda commented, “it was a good opportunity go along and keep up with the latest developments on the Giga Factory project. WEAF will keep its members and stakeholders updated with the latest news as it emerges”.